Gas Lift is a principal method of secondary oil recovery utilized by operators in basins throughout the world.

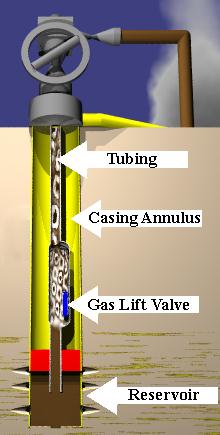

Gas lift does not require the tooling capital costs compared with other forms of artificial lift such as rod pumps and the electric submersible pump (esp). The gas lift process involves injecting gas through the tubing / casing annulus. The injected gas aerates the fluid to reduce its density. In this way, the formation pressure is able to lift the oil and water column and forces the fluid out of the wellbore. Gas may be injected continuously or intermittently, depending on the producing characteristics of the well and the arrangement of the gas lift equipment.

Although the gas is recovered from the oil at a later separation stage, the process requires energy to drive a compressor in order to raise the pressure of the gas to a level where it can be re-injected.

Types of tools - the gas lift mandrel is a device installed in the tubing string of a gas lift well onto which or into which a gas lift valve is fitted. There are two common types of mandrels. In a conventional gas-lift mandrel, a gas lift valve is installed as the tubing is placed in the well. Thus, to replace or repair the valve, the tubing string must be pulled. On the other hand, in the side pocket mandrel the valve is installed and removed by wireline while the mandrel is still in the well, eliminating the need to pull the tubing to repair or replace the valve.

A gas lift valve is an apparatus that is installed on (or in) a gas-lift mandrel, which is put on the production tubing of a gas lift well. Tubing and casing pressures cause the valve to open and close, thus allowing gas to be injected into the fluid in the tubing to cause the fluid to rise to the surface.

Gas lift mandrels are "tubing retrievable" as they are deployed and retrieved attached to the production tubing.

Gas lift does not require the tooling capital costs compared with other forms of artificial lift such as rod pumps and the electric submersible pump (esp). The gas lift process involves injecting gas through the tubing / casing annulus. The injected gas aerates the fluid to reduce its density. In this way, the formation pressure is able to lift the oil and water column and forces the fluid out of the wellbore. Gas may be injected continuously or intermittently, depending on the producing characteristics of the well and the arrangement of the gas lift equipment.

The amount of gas to be injected to maximize oil production varies based on well conditions and subsurface geometries. Too much or too little injected gas will result in less than maximum production. Generally, the optimal amount of injected gas is determined by well tests, where the rate of injection is varied and liquid production (oil and many times water) is measured.

Although the gas is recovered from the oil at a later separation stage, the process requires energy to drive a compressor in order to raise the pressure of the gas to a level where it can be re-injected.

Types of tools - the gas lift mandrel is a device installed in the tubing string of a gas lift well onto which or into which a gas lift valve is fitted. There are two common types of mandrels. In a conventional gas-lift mandrel, a gas lift valve is installed as the tubing is placed in the well. Thus, to replace or repair the valve, the tubing string must be pulled. On the other hand, in the side pocket mandrel the valve is installed and removed by wireline while the mandrel is still in the well, eliminating the need to pull the tubing to repair or replace the valve.

A gas lift valve is an apparatus that is installed on (or in) a gas-lift mandrel, which is put on the production tubing of a gas lift well. Tubing and casing pressures cause the valve to open and close, thus allowing gas to be injected into the fluid in the tubing to cause the fluid to rise to the surface.

Gas lift mandrels are "tubing retrievable" as they are deployed and retrieved attached to the production tubing.

Gas lift is also a good choice with highly deviated wells.

ReplyDelete